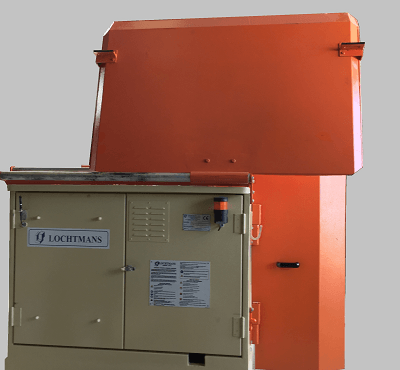

LGR 4 1S INVERTER PLC

The LGR4 IPTS diamond wire machine with INVERTER, PLC and TOUCH SCREEN for cutting marble, granite and stones, is suitable for making large and particularly difficult cuts, and thanks to the installed display, it is possible to set and monitor all parameters cutting.

INVERTER

The machine is equipped with an inverter to allow it to vary the speed of the diamond wire from 0 to 40 m/sec and an inverter for pulling in order to vary the tension load on the wire. The use of the inverter allows to adjust the speed of the diamond wire during all the cutting phases, and to have gradual starts and stops. Therefore ideal for hard and abrasive materials and for cuts of considerable size and difficulty. The machine is equipped with a forced ventilation system with air filtering to reduce the operating temperatures of the inverter.

PLC

The installation of the PLC allows intelligent solutions for the control and automation of the machine during the start-up, execution and end of the cutting phases. Thanks to this new system it is possible to have real-time information on the state of the machine, absorption of the motor, speed of the diamond wire, wire tension etc., information in the event of equipment failure, breakage of the diamond wire and lack of flow of water.

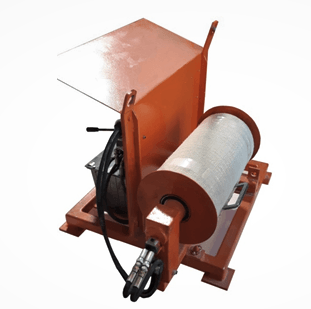

LOAD CELL (on request)

The purpose of the load cell application is to measure and limit the stress to which the diamond wire is subjected during cutting operations. During the automatic cutting cycle, the tension of the diamond wire is reduced when the maximum load threshold is exceeded and is reactivated when it drops below this value again.

SAFETY PROTECTIONS

Lochtmans's diamond wire machines are equipped with accident prevention means to avoid any risks taken by those who work near the machines, as the breaking of a diamond wire can generate the projection of circuit elements (pearls, spacers springs or parts of a cable) and a possible whiplash of the broken cable.

REMOTE CONTROL PANEL - TOUCH SCREEN

The new remote-control panel, equipped with a graphic touch screen terminal, allows to carry out the traditional adjustment and control operations of the machine and the display of status messages relating to cutting and equipment.

RADIO REMOTE CONTROL (on request)

The total adjustment and control of the machine can take place through the most innovative and radio safe remote control, from which it is possible to carry out all positioning, adjustment, and machine control and cutting management operations. The display allows you to view the cutting parameters.

LGR4 1S PI RADIO REMOTE CONTROL

The adjustment and total control of the machine can take place through the most innovative and safe radio remote control, from which it is possible to carry out all the positioning, adjustment, and machine control and cutting management operations. The display allows you to view all the cutting parameters.

- receiver unit inside the machine

- portable transmitter unit

- 6 proportional levers

- 8 fixed position selector

- emergency button in category PL and EN13849 and SIL 3 EN61508

- display with parameter index, selection, validation, consultation.

- 2 removable Ni-Mh batteries with battery charger

- frequency parameterizable from 418 to 918 MHz

- degree of protection IP 65

- Range about 40-70 meters

NEW TAX CREDIT 4.0

The LGR4-1S-PI cutting machine with diamond wire produced by Lochtmans meets the criteria of the 4.0 tax credit, with the possibility of counting on significant tax savings.

LGR4-V4.0 module

The LGR4-V4.0 module is the complete solution that automatically collects and processes production data in real time of the LGR4-PI series diamond wire saw machine. The installation offers real-time monitoring of machine parameters and performance, which can be viewed thanks to a completely customizable interface. The data can be managed locally, or sent over the network using one of the safest market standards currently available. The basic installation also includes the preventive maintenance assistance functions, the calculation of the efficiency indices, the sending of messages on the operating status and the monitoring of tool consumption. It is possible through the application and the PLC to easily generate files and reports, obtain various parameters such as cutting time, idle time, downtime and more. The PLC offers real-time machine monitoring, allowing to detect energy consumption, water consumption, and consumption of the diamond wire. The PLC on the machine can thus become a network solution that sends data to the company server, from which it is possible to record production data and monitor from multiple locations, accessing data from anywhere and being viewed on any device with a browser and an Internet connection.

Among the various values that can be imported from the PLC, the most significant are:

- energy consumption

- work execution time

- water consumption by installing an electronic flow meter

- tool working hours

- downtime

- fault list

- maintenance monitoring

- and more to be chosen by the customer

The PLC can also be programmed to send messages to operators in the event of machine faults or anomalies, such as breaking the diamond wire, lack of water, overload of the flywheel motor, overload of the towing motor and of the hydraulic power unit motor, anomalies in the electrical control components and protection devices, etc., allowing the operator to know the restoration interventions to be performed and recording their history on the company server.

Obviously, in order to obtain the data, it is necessary for operators to enter some initial parameters relating to the cuts to be made, such as the size, length of the diamond wire and the relative batch number in order to have a careful precise analysis of the overall data The communication of the machine to the company's IT systems both for the acquisition of information and for the continuous monitoring functions and process parameters takes place via the WI-FI antenna access point or UMTS card with Modbus TCP IP protocol.

This also makes it possible to carry out remote maintenance and remote diagnosis of the machine.