LGR 4 1S INVERTER

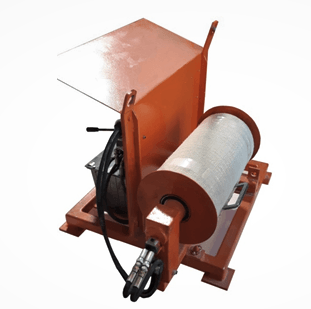

The LGR4 INVERTER is the latest production diamond wire cutting machine, it is the result of agelong experience and innovative applications in the design and construction of this type of machine. It is intended for use in marble, granite and ornamental stone quarries, to perform cuts both at the quarry front as well as for block squaring.

INVERTER

The machine is equipped with an inverter to allow it to vary the speed of the diamond wire from 0 to 40 m/sec and an inverter for pulling in order to vary the tension load on the wire. The use of the inverter allows to adjust the speed of the diamond wire during all the cutting phases, and to have gradual starts and stops. Therefore ideal for hard and abrasive materials and for cuts of considerable size and difficulty. The machine is equipped with a forced ventilation system with air filtering to reduce the operating temperatures of the inverter.

LOAD CELL (on request)

The purpose of the load cell application is to measure and limit the stress to which the diamond wire is subjected during cutting operations. During the automatic cutting cycle, the tension of the diamond wire is reduced when the maximum load threshold is exceeded and is reactivated when it drops below this value again. SAFETY PROTECTIONS

Lochtmans's diamond wire machines are equipped with accident prevention means to avoid any risks taken by those who work near the machines, as the breaking of a diamond wire can generate the projection of circuit elements (pearls, spacers springs or parts of a cable) and a possible whiplash of the broken cable.

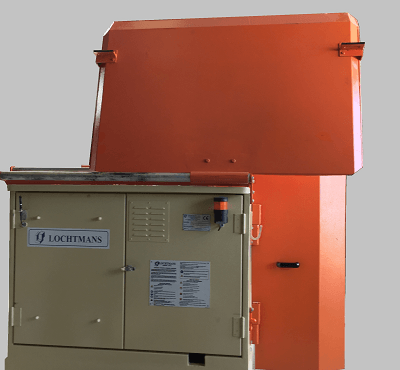

REMOTE CONTROL PANEL

The adjustment and control of the machine takes place via the classic control panel that can be remotely positioned with a 15 mt. long connection cable. It carries out all positioning, adjustment the machine, control and cutting operations. The remote-control panel is equipped with a convenient positioning stand and a box with a closing door. The switchboard is equipped with an emergency button.

RADIO REMOTE CONTROL (on request)

The total adjustment and control of the machine can take place through the most innovative and radio safe remote control, from which it is possible to carry out all positioning, adjustment, and machine control and cutting management operations. The display allows you to view the cutting parameters.

LGR4 1S I RADIO REMOTE CONTROL

The adjustment and total control of the machine can take place through the most innovative and safe radio remote control, from which it is possible to carry out all the positioning, adjustment, and machine control and cutting management operations. The display allows you to view all the cutting parameters. In case of need, it can be connected to the machine using the 15 mt cable provided.

- receiver unit inside the machine

- portable transmitter unit

- 2 proportional levers

- 3 fixed position selectors

- 2 potentiometers

- 3 buttons

- emergency button in category PL and EN13849 and SIL 3 EN61508

- display with parameter index, selection, validation, consultation.

- 2 removable Ni-Mh batteries with battery charger

- degree of protection IP 65

- Range about 40-70 meters